Sustainability of 3D Construction Printing Technology: A Review on Research Trends and Developments

Conference Paper · November 2023

5 Authors, including:

Claire Flemmer Massey University. 37 PUBLICATIONS 459 CITATIONS

Ding Wen Bao RMIT University 49 PUBLICATIONS 401 CITATIONS

Expertise Areas

This paper had been presented at the 46th Australasian Universities Building Education Association (AUBEA) 2023 Conference, Auckland, New Zealand, 26-28 November 2023.

Expertise Areas

Asad Ur Rehman Bajwa1, 1 Massey University, New Zealand Claire Flemmer1, Massey University, New Zealand

Don Samarasinghe1, Massey University, New Zealand Ding Wen Bao2, 2 RMIT University, Australia

Regan Potangaroa1, Massey University, New Zealand

*abajwa@massey.ac.nz (Asad Ur Rehman Bajwa)

Abstract

Expertise Areas

3D printing (3DP) can potentially improve environmental sustainability in construction activities by reducing energy use, waste, and adverse ecological impacts. The construction industry can capitalise on the opportunity to accelerate innovation by adopting 3DP as a means of sustainability to contribute towards 2050 Zero Carbon targets of lowering New Zealand’s gross, net, and target accounting emissions by 30%, 70%, and 60% respectively, compared with the 2020 levels.

Expertise Areas

This study employs literature review analysis as a research method to explore the literature on 3DP in construction. It assesses the sustainability of 3DP, considering not only its environmental sustainability but also its economic and social sustainability. In addition, it analyses the state of the art of 3DP, using an overview of recent projects by commercial 3DP companies covering a range of applications in several countries.

Expertise Areas

It summarizes the advantages and the challenges of 3DP and identifies the main research gaps. Chief amongst these is the need to identify the mixtures of materials which can be used in the printing process and to quantify the structural and thermal performance of the printed structure. More research is needed on the application of Life Cycle Assessment of 3DP as the metric for evaluating its environmental impact. The research needs to be a collaborative effort between academia and industry. The roadmap for further research and the assessment of 3DP as an emerging technology provide insights for improving the built environment and enhancing energy efficiency.

Introduction

Expertise Areas

The growth or decline of the construction sector is a key economic indicator for a region’s financial prowess; a thriving construction sector reflects economic strength, while a downturn in construction activity signals an economic slump (Khaertdinova et al., 2021). Before the start of the Covid-19 pandemic, global construction expenditure reached a staggering US$ 4.5 trillion, and it is predicted to be US$ 13.3 trillion by 2025 and US$ 13.9 trillion by 2037 (Oxford Economics, 2023). Such a substantial growth projection underscores the sector’s potential to drive global green economic development and prosperity (Oxford Economics, 2023). The sector contributed 36% to global energy usage and 39% to global carbon dioxide emissions in 2018, primarily from building materials and manufacturing activities (International Energy Agency, 2019). Furthermore, the sector’s greenhouse gas (GHG) emissions are predicted to increase by 37.5% by 2050 (Jeong et al., 2021).

Expertise Areas

The construction industry in New Zealand is the 3rd largest employment sector, employing 10% of the total workforce and contributing 6.7% of the country’s GDP (MBIE, 2022). Before Covid-19, New Zealand experienced a 5% rise in carbon dioxide levels from the 2010 baseline (Stats NZ, 2020). Additionally, one-fifth of the total GHG emissions in New Zealand is linked to the construction sector (Akan et al., 2017).

Expertise Areas

The construction sector’s exponential rise in carbon footprint requires substantial efforts to reduce its negative environmental impact (Rajabi et al., 2022). This can be achieved by transitioning to non-conventional construction methods (Cramer, 2023). Novel technologies such as modular construction (Thai et al., 2020) and robotic construction (Xiao et al., 2022) are already contributing to the decarbonisation of the sector (Labaran et al., 2022). Another innovative technology with the potential to improve construction sustainability is additive manufacturing or 3D printing (3DP) (Ali et al., 2022; El-Sayegh et al., 2020; Kazemian et al., 2022; Mozaffari et al., 2023; Pan et al., 2021; Tuvayanond and Prasittisopin, 2023). However, its adoption has been slow compared with its use in biomedical and food industries (Chua and Leong, 2014; Khoshnevis et al., 2006). A detailed review of 3DP technology in the construction industry is the focus of this article, and Section 2 provides the background.

Literature Review

Expertise Areas

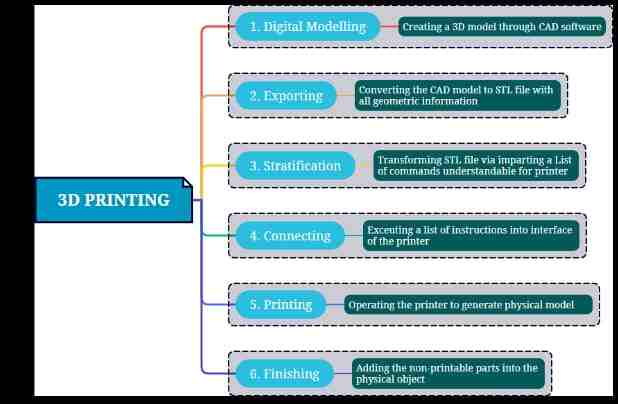

3D printing (also known as ‘additive manufacturing’) is a process in which a printer assembles materials to create a physical object using an instruction-based digital file derived from a Computer-Aided Design (CAD) drawing of the object (Perrot, 2019; Shahrubudin et al., 2019). The process is shown in Figure 1.

Expertise Areas

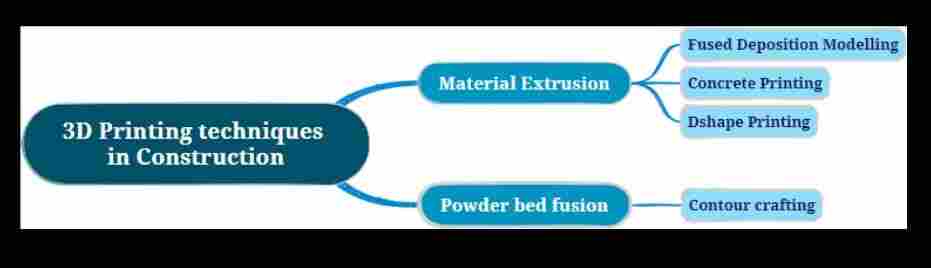

3DP encompasses a wide range of technologies such as stereolithography, ink jetting and direct energy deposition in pharmaceutical, food and metallic products (Levato et al., 2023; Nazir et al., 2022; Petersmann et al., 2023). However, in the construction industry the two primary technologies used (Figure 2) are Material Extrusion and Powder Bed

fusion or contour crafting (El-Sayegh et al., 2020; Khoshnevis et al., 2006; Ngo et al., 2018). Material Extrusion is the most common and encompasses processes such as fused deposition modelling (Wasti and Adhikari, 2020), 3D concrete printing and Dshape printing (Colla et al., 2013). New research is investigating the use of Binder Jet technology in concrete 3DP as a potential fourth Material Extrusion process (Kazemian et al., 2022; Volpe et al., 2022).

Expertise Areas

Interest in 3DP technology and its use in the construction sector has grown rapidly and is predicted to become increasingly used in the mid-21st century (Skilton and Hovsepian, 2018; Volpe et al., 2022). Table 1 summarizes the recent research themes. Chief amongst these is its sustainability potential (Hossain et al., 2020). Ibrahim et al. (2022) showed that in extreme climates 3DP could achieve up to 49% lower carbon footprint compared with conventional construction, while being 78% more cost-effective. Several other studies found that 3DP construction improved productivity, minimized resource use, lowered waste, decreased GHG emissions and reduced operational costs (El-Sayegh et al., 2020; Singh et al., 2021). However, there are also doubts on the feasibility of 3DP as a sustainable solution, particularly for large-scale construction projects (Bhushan Jindal and Jangra, 2023; Nilimaa, 2023). There are also reservations about its actual environmental impact, the energy efficiency of the printing process and the thermomechanical performance of the printed structure (Perrot, 2019).

Table 1. Research themes relating to 3DP technology in construction.

Key research themes | Source(s) |

Opportunities and constraints for 3DP | (Cascone et al., 2020; Kazemian et al., 2022) |

Improving printability and structural performance | (Chen et al., 2020) |

Offsite and onsite applications of 3DP | (Jipa and Dillenburger, 2022) |

Compressive and flexural strength of the objects | (Marcucci et al., 2022) |

Cost-effectiveness, productivity, and high design intricacy | (Bao et al., 2022) |

Thermomechanical performance of objects | (Tirth and Ghori, 2021) |

Technology readiness and prospects of 3DP | (Ma et al., 2022) |

Optimizing printing parameters for high printing quality | (Zhang and Sanjayan, 2023) |

Development of new materials and composites | (Gauss and Pickering, 2023; Inayath Basha et al., 2023; Nilimaa, 2023) |

Environmental sustainability of 3DP | (Almeida et al., 2021; Batikha et al., 2022; Garrett, 2014; Gebler et al., 2014; Hossain et al., 2020; Ibrahim et al., 2022; Kanyilmaz et al., 2022; Nilimaa, 2023; Perrot, 2019; Singh et al., 2021) |

Expertise Areas

A second area of research focusses on the materials used in construction 3DP. The rheology of the material must be suitable for extrusion and the printed structure must have appropriate strength, thermal insulation, and aesthetics. There are several studies into cementitious material properties (Freire et al., 2021) and the effect of material selection on anisotropic behavior and mechanical properties (Ngo et al., 2018). Studies on the use of sustainable materials include the use of glass, ceramics and cement mortar (Volpe et al., 2022), the use of fly ash, silica fume and aggregates as a replacement for cement (Samudrala et al., 2023) and the use of green additives, industrial waste materials, materials, porous concrete, light concrete, and locally sourced materials (Nilimaa, 2023; Volpe et al., 2022).

Expertise Areas

The aim of this article is to assess the research on 3DP in construction and address the research question of whether it has the potential to provide a more environmentally sustainable construction method. It also looks at the advantages of 3DP and the barriers to its uptake by the construction sector. The assessment relies on a review of recent industry webinars and workshops and academic literature.

Research Methodology

Expertise Areas

The research approach and justification for this narrative literature review follow the principles of (Saunders et al., 2009) and are summarized in Table 2.

Table 2. Research Methodology and Justification

Research Design | Choice | Justification of choice |

Philosophy | Interpretivist | Qualitative and quantitative observations will be interpreted in the context of generating themes in the literature on 3D printing. |

Approach | Inductive | Observations and data are used to construct a theory of primary themes concerning 3D printing. |

Strategy | Archival research | The research draws on existing literature related to 3D printing. |

Methods | Multi-method | Qualitative analysis involving both thematic analysis and content analysis, in addition to quantitative data on 3D printing. |

Tools | Literature search engine data, industry webinar/workshop review, thematic analysis, content analysis | A longitudinal study of the literature generated from search engines (Scopus, Discover, Google Scholar), a review of recent industry webinars and workshops, with thematic and content analysis. |

Expertise Areas

We choose “Scopus”, a peer reviewed literature search database, for indexing and abstracting with full-text websites generated by Elsevier Co. Scopus has a reliable, rapid, relevant, and latest availability of research records through excellent navigation.

“Search within” box in the interface of Scopus allowed to explore documents by applying the relevant filters across a diverse range of fields (Title-Abstract-Keyword etc.). The document search command consisting of field code (ALL) and keywords based on the Technology (3D printing), discipline (construction) and perspective (sustainability) initially yielded 17760 records, for example (ALL “3D printing” AND construction OR Build* AND sustain*). Later, the field codes TITLE-ABS-KEY (Title, Abstract and

Expertise Areas

Keywords) were applied by choosing “Advanced document search” option resulted into 676 number of documents. Further sorting was applied based on the ‘field of study’ and type of document (Article papers). Since the Keywords and scope of this study focus on technical aspects of 3DP, so Subject area filter selected ‘Engineering’ and ‘Energy’ as the chosen fields in the database to lessen the number of the records up to 350.

Expertise Areas

The review timeframe (focusing on the last 8 years) and reliance on thematic and content analysis assure the reliability and validity of the research findings. The restriction of only articles written in English is a limitation of the method since findings from countries like China may have been missed. Also included in the review is information from industry webinars and workshops held in 2022 and 2023, since these show the current 3DP practice.

Findings and Discussion

Expertise Areas

Most of the research records primarily address three aspects of 3D printing: firstly, the recent projects and research of commercial 3DP companies, secondly, the potential of 3DP as an environmentally sustainable construction method, and thirdly, the advantages and the barriers to its uptake by the construction sector.

4.1 Overview of Current Projects and Research by Commercial 3DP Companies

Expertise Areas

Webinars and workshops in 2022 and 2023 showcased the projects that have been completed by commercial 3DP companies and their areas of research (Table 3).

Table3. Commercial 3DP company construction projects and research areas

Application(s) and Source | Findings |

Living sea walls by (Kind Designs, 2023). | 3DP sea walls to protect against erosion and storms in the face of rising sea levels. This could help foster marine biodiversity by providing a nearly natural habitat. |

Assorted structures by (CyBe construction, 2023b) | 3DP projects including an R&D drone laboratory in Dubai, housing (Studio 2030 in Saudi Arabia), an iconic building (De Vergaderfabiek in |

Europe), a guardhouse (La Sphère in France), Sapporo Park restrooms in Japan, and Robust Villa in Curaçao. | |

Building components and sculptures by (QOROX, 2023) | 3DP with innovative, imported water-impenetrable materials. Projects include small building components, walls and sculptures. The company has achieved 75% faster construction speed, 70% less waste, and 40% lower CO2 emissions than traditional methods, making it a promising solution for sustainable construction in New Zealand. |

3DP cost, by (CyBe Construction, 2022) | Cost calculation in building design through 3D printing. |

3D printing systems, (CyBe Construction, 2023c) | Contour crafting system is used for 3D printing structural components. Fixed, Mobile, Track, and Gantry type 3D printing systems are available in the southern hemisphere. |

Assorted 3D concrete printing projects, by QOROX and ICON construction (QOROX, 2023) | Huia house, Paremoremo house, rain garden for conserving water, traffic islands, Piles Eco collars and Iconic Daycare in New Zealand. Ongoing collaboration with the government to address the housing crisis in New Zealand. |

3DP housing by (CyBe Construction, 2023a). | Research into the opportunities for affordable housing through 3DP printing to address the housing crisis in South Africa. Economic sustainability rather than environmental sustainability |

Expertise Areas

The commercial 3DP companies have used the technology to create structural components (such as walls, and traffic islands) and small buildings (Tay et al., 2017). Their research efforts include investigations into both environmental sustainability (minimizing waste and GHG emissions) and economic sustainability and the latter may contribute to social sustainability, since faster and less expensive construction can be used to solve housing demand

4.2 Assessment of the Sustainability of 3DP Construction

Expertise Areas

A number of authors have identified 3DP construction technology more environmentally sustainable than conventional construction, with the exception of (Salandin et al., 2022) who argued 3DP to be less sustainable at the present because of higher use of cement mortar. Conversely, majority of the research records have identified rapid processing and less material usage to be reasons for sustainability of 3DP (Mozaffari et al., 2023). Furthermore, efficient material use is critical to the environmental impact (Bhushan Jindal and Jangra, 2023) and 3DP cement has high carbon emission (Janssens-Maenhout et al., 2013).

Expertise Areas

Sustainability could be improved through the use of printable mixtures made from construction waste and recycled materials, but a research gap exists in developing such mixtures (Lazorenko and Kasprzhitskii, 2022; Pasupathy et al., 2023; Raza and Zhong, 2022). In the operational phase, there is some indication that the printed envelope has good energy efficiency and thermal performance (AlZahrani et al., 2022; de Rubeis et al., 2022) but the studies are limited and there remain doubts about the overall thermal performance (Dhangar et al., 2023; Volpe et al., 2023). Life Cycle Assessment (LCA) provides a framework for assessing environmental impact over the entire lifecycle (not just the operational phase of building) and can be used to determine the effect of alternative printing material mixes (Fernandez et al., 2023).

Expertise Areas

Initial LCA studies have found that 3DP has a lower environmental impact than conventional construction, but the studies are restricted to a single printing mixture, locally sourced materials, and differing size and design in the houses being compared (Long et al., 2019; Taylor et al., 2023; Zhang and Sanjayan, 2023). This points to a second research gap, namely that more rigorous and extensive LCA is needed before the environmental sustainability of 3DP is determined. Finally, Flatt and Wangler (2022) note that the environmental impact of 3DP must be considered alongside its social and economic sustainability.

Expertise Areas

While recent research into new 3DP methods have demonstrated economic viability (Ambily et al., 2023; Cruz et al., 2023; Nguyen-Van et al., 2023), this remains an important area for future research. From the social sustainability viewpoint, the rapid construction of 3DP structures may offer a solution to the housing supply problem (CyBe construction, 2023b; QOROX, 2023).

4.3 The Advantages and Challenges in the Use of 3DP in Construction

Expertise Areas

A synthesis of the literature in the previous sections has shown several advantages and challenges in the use of 3DP as an emerging construction technology and these are summarised in Figure 4. The main advantages relate to efficient construction and to social and economic sustainability, but the question of environmental sustainability remains unanswered. The main challenges relate to the materials specification, the technical difficulties (associated with the printing equipment and software), the knowledge gap of the stakeholders (in the project management, the practical application, and the regulatory issues), and the unknown performance parameters of the printed structure. Future research will need to address these challenges.

Conclusion and Further Research

Expertise Areas

The current use of 3DP in construction is confined to small-scale projects. There are several challenges associated with it, such as determining the material mixtures which can be used and determining the structural and thermal behaviour of the printed structures

Expertise Areas

These, together with the knowledge gap of the stakeholders, mean that it is unlikely that 3DP construction will become widespread soon. Preliminary work shows that 3DP construction may be economically and socially sustainable but the question of whether it is environmentally sustainable remains unanswered. The findings thus far are mixed and more rigorous assessment, using LCA, is needed. The success of 3DP technology relies on the cooperative efforts of industry and academia in the ongoing research into both the technical factors and the environmental sustainability assessment through the LCA metric. This study would further expand its scope over the course of next three years: (1) Collecting and Analysing data (2) Designing the experiment thermal performance of 3DP elements, and (3) Theoretical framework development for further research.

References

- Akan, M. Ö. A., Dhavale, D. G., & Sarkis, J. (2017). Greenhouse gas emissions in the construction industry: An analysis and evaluation of a concrete supply chain. Journal of Cleaner Production, 167, pp 1195-1207.

- Ali, M. H., Issayev, G., Shehab, E., & Sarfraz, S. (2022). A critical review of 3D printing and digital manufacturing in construction engineering. Rapid Prototyping Journal, 28(7), pp 1312-1324.

- Almeida, H., Pei, E., & Vitorino, L. (2021). Sustainablity for 3D Printing. In

- Sustainability for 3D Printing (pp. 1-13). Springer.

- AlZahrani, A. A., Alghamdi, A. A., & Basalah, A. A. (2022). Computational Optimization of 3D-Printed Concrete Walls for Improved Building Thermal Performance [Article]. Buildings, 12(12), Article 2267.

- Ambily, P. S., Kaliyavaradhan, S. K., & Rajendran, N. (2023). Top challenges to widespread 3D concrete printing (3DCP) adoption–A review. European Journal of Environmental and Civil Engineering, 13(827).

- Bao, D. W., Yan, X., & Xie, Y. M. (2022). Fabricating topologically optimized tree-like pavilions using large-scale robotic 3D printing techniques. Journal of the International Association for Shell and Spatial Structures, 63(2), pp 122-131.

- Batikha, M., Jotangia, R., Baaj, M. Y., & Mousleh, I. (2022). 3D concrete printing for sustainable and economical construction: A comparative study. Automation in Construction, 134, Article 104087.

- Bhushan Jindal, B., & Jangra, P. (2023). 3D Printed Concrete: A comprehensive review of raw material’s properties, synthesis, performance, and potential field applications. Construction and Building Materials, 387, Article 131614.

- Cascone, P., Laddaga, M., & Forestiero, F. (2020). DIGITAL CONSTRUCTION: 3D Printing for Performative Houses. In RILEM Bookseries (Vol. 28, pp. 804-813). Springer.

- Chen, Y., Chaves Figueiredo, S., Li, Z., Chang, Z., Jansen, K., Çopuroğlu, O., & Schlangen, E. (2020). Improving printability of limestone-calcined clay-based cementitious materials by using viscosity-modifying admixture. Cement and Concrete Research, 132, Article 106040.

- Chua, C. K., & Leong, K. F. (2014). 3D Printing and additive manufacturing: Principles and applications (with companion media pack)-of rapid prototyping. World Scientific Publishing Company.

- Colla, V., Dini, E., Canessa, E., Fonda, C., & Zennaro, M. (2013). Large scale 3D printing: From deep sea to the moon. Low-Cost 3D Printing, for Science, Education & Sustainable Development, pp 127-132.

- Cramer, J. (2023). How circular economy and digital technologies can support the building sector to cope with its worldwide environmental challenge? npj Urban Sustainability, 3(1), 28.

- Cruz, G., Dizon, J. R. C., Farzadnia, N., Zhou, H., Margarito, M., Garcia, J. A., Liza, F. P., & Advincula, R. C. (2023). Performance, applications, and sustainability of 3D-printed cement and other geomaterials. MRS Communications, 13, 385-399.

- CyBe Construction. (2022). 5 Steps to Calculate Your Profit by 3D Concrete Printing.

- Retrieved 16/10/2023 from https://cybe.eu/webinars/cost-calculation-roi/ CyBe Construction. (2023a). 3DCP as a Solution for the Housing Crisis in South

- Africa. https://cybe.eu/webinars/webinar-south-africa/

- CyBe construction. (2023b). Printed house conference. Retrieved 16/10/2023 from https://cybe.eu/webinars/printed-housing-conference/

- CyBe Construction. (2023c). Printer Options. Retrieved 16/10/2023 from https://cybe.eu/webinars/webinar-printer-options/

- de Rubeis, T., Ciccozzi, A., Giusti, L., & Ambrosini, D. (2022). The 3D Printing Potential for Heat Flow Optimization: Influence of Block Geometries on Heat Transfer Processes [Article]. Sustainability (Switzerland), 14(23), Article 15830.

- Dhangar, M., Chaturvedi, K., Mili, M., Patel, S. S., Khan, M. A., Bhargaw, H. N., Srivastava, A. K., & Verma, S. (2023). Emerging 3D printed thermal insulating materials for sustainable approach: A review and a way forward. Polymers for Advanced Technologies, 34(5), pp 1425-1434.

- El-Sayegh, S., Romdhane, L., & Manjikian, S. (2020). A critical review of 3D printing in construction: Benefits, challenges, and risks. Archives of Civil and Mechanical Engineering, 20, pp 1-25.

- Fernandez, L. I. C., Caldas, L. R., & Mendoza Reales, O. A. (2023). Environmental evaluation of 3D printed concrete walls considering the life cycle perspective in the context of social housing. Journal of Building Engineering, 74, Article 106915.

- Flatt, R. J., & Wangler, T. (2022). On sustainability and digital fabrication with concrete. Cement and Concrete Research, 158, Article 106837.

- Freire, T., Brun, F., Mateus, A., & Gaspar, F. (2021). 3D printing technology in the construction industry Sustainability and Automation in Smart Constructions: Proceedings of the International Conference on Automation Innovation in Construction (CIAC-2019), Leiria, Portugal, https://link.springer.com/chapter/10.1007/978-3-030-35533-3_19

- Garrett, B. (2014). 3D printing: new economic paradigms and strategic shifts. Global Policy, 5(1), pp 70-75.

- Gauss, C., & Pickering, K. L. (2023). A new method for producing polylactic acid biocomposites for 3D printing with improved tensile and thermo-mechanical performance using grafted nanofibrillated cellulose. Additive Manufacturing, 61, 103346.

- Gebler, M., Schoot Uiterkamp, A. J. M., & Visser, C. (2014). A global sustainability perspective on 3D printing technologies. Energy Policy, 74, pp 158-167.

- Hossain, M. A., Zhumabekova, A., Paul, S. C., & Kim, J. R. (2020). A review of 3D printing in construction and its impact on the labor market. Sustainability, 12(20), 8492.

- Ibrahim, I., Eltarabishi, F., Abdalla, H., & Abdallah, M. (2022). 3D Printing in sustainable buildings: Systematic review and applications in the United Arab Emirates. Buildings, 12(10), 1703.

- Inayath Basha, S., Ur Rehman, A., Aziz, M. A., & Kim, J. H. (2023). Cement Composites with Carbon‐Based Nanomaterials for 3D Concrete Printing

- Applications–A Review. The Chemical Record, 23(4), e202200293. https://doi.org/doi.org/10.1002/tcr.202200293tcr.wiley-vch.de

- International Energy Agency. (2019). Global Status Report for Buildings and Construction 2019. https://iea.blob.core.windows.net/assets/3da9daf9-ef75- 4a37-b3da- a09224e299dc/2019_Global_Status_Report_for_Buildings_and_Construction.pd f

- Janssens-Maenhout, G., Muntean, M., Peters, J., & Olivier, J. (2013). Trends in global CO2 emissions: 2013 Report. PBL Netherlands Environmental Assessment Agency, The Hague, 274. https://doi.org/https://doi.org/10.1051/e3sconf/202127410021

- Jeong, Y.-S., Cho, S., Mun, S.-H., & Ji, C. (2021). Scenario to reduce greenhouse gas emissions in building sector towards the goal of carbon neutrality by 2050.

- Journal of the Architectural Institute of Korea, 37(10), pp 189-197.

- Jipa, A., & Dillenburger, B. (2022). 3D Printed Formwork for Concrete: State-of-the- Art, Opportunities, Challenges, and Applications [Review]. 3D Printing and Additive Manufacturing, 9(2), pp 84-107.

- Kanyilmaz, A., Demir, A. G., Chierici, M., Berto, F., Gardner, L., Kandukuri, S. Y., Kassabian, P., Kinoshita, T., Laurenti, A., & Paoletti, I. (2022). Role of metal 3D printing to increase quality and resource-efficiency in the construction sector. Additive Manufacturing, 50, Article 102541.

- Kazemian, A., Seylabi, E., & Ekenel, M. (2022). Concrete 3D Printing: Challenges and Opportunities for the Construction Industry. Innovation in Construction: A Practical Guide to Transforming the Construction Industry, pp 277-299.

- Khaertdinova, A., Maliashova, A., & Gadelshina, S. (2021). Economic development of the construction industry as a basis for sustainable development of the country E3S Web of Conferences,

- Khoshnevis, B., Hwang, D., Yao, K.-T., & Yeh, Z. (2006). Mega-scale fabrication by contour crafting. International Journal of Industrial and Systems Engineering, 1(3), pp 301-320.

- Kind Designs. (2023). Living Seawalls, 3D marine construction in Miami. Retrieved 16/10/2023 from https://www.youtube.com/watch?v=nakei4t1JkU

- Labaran, Y. H., Mathur, V. S., Muhammad, S. U., & Musa, A. A. (2022). Carbon footprint management: A review of construction industry. Cleaner Engineering and Technology, 9, 100531.

- Lazorenko, G., & Kasprzhitskii, A. (2022). Geopolymer additive manufacturing: A review [Review]. Additive Manufacturing, 55, Article 102782.

- Levato, R., Dudaryeva, O., Garciamendez-Mijares, C. E., Kirkpatrick, B. E., Rizzo, R., Schimelman, J., Anseth, K. S., Chen, S., Zenobi-Wong, M., & Zhang, Y. S. (2023). Light-based vat-polymerization bioprinting. Nature Reviews Methods Primers, 3(1), pp 47.

- Long, W.-J., Tao, J.-L., Lin, C., Gu, Y.-c., Mei, L., Duan, H.-B., & Xing, F. (2019).

- Rheology and buildability of sustainable cement-based composites containing micro-crystalline cellulose for 3D-printing. Journal of Cleaner Production, 239, Article 118054.

- Ma, G., Buswell, R., Leal da Silva, W. R., Wang, L., Xu, J., & Jones, S. Z. (2022). Technology readiness: A global snapshot of 3D concrete printing and the frontiers for development. Cement and Concrete Research, 156, Article 106774.

- Marcucci, A., Kompella, S. K., Lo Monte, F., Levi, M., & Ferrara, L. (2022). Early Age Shear and Tensile Fracture Properties of 3D Printable Cementitious Mortar to Assess Printability Window. In RILEM Bookseries (Vol. 37, pp. pp 337-342).

- MBIE. (2022). Building and construction sector trends annual report 2022. https://www.mbie.govt.nz/dmsdocument/25439-building-construction-sector- trends-annual-report-2022

- Mozaffari, S., Bruce, M., Clune, G., Xie, R., McGee, W., & Adel, A. (2023). Digital design and fabrication of clay formwork for concrete casting [Article].

- Automation in Construction, 154, Article 104969.

- Nazir, A., Liao, M. C., Zhu, Y. W., & Nazir, U. (2022). Design and Evaluation of Asphalt Concrete Incorporating Plastic Aggregates Fabricated Using 3D Printing Technology [Article]. 3D Printing and Additive Manufacturing, 9(3), pp 212- 222.

- Ngo, T. D., Kashani, A., Imbalzano, G., Nguyen, K. T. Q., & Hui, D. (2018). Additive manufacturing (3D printing): A review of materials, methods, applications and challenges [Review]. Composites Part B: Engineering, 143, pp 172-196.

- Nguyen-Van, V., Li, S., Liu, J., Nguyen, K., & Tran, P. (2023). Modelling of 3D concrete printing process: A perspective on material and structural simulations [Review]. Additive Manufacturing, 61, Article 103333.

- Nilimaa, J. (2023). Smart materials and technologies for sustainable concrete construction. Developments in the Built Environment, 15, Article 100177.

- Oxford Economics. (2023). Global construction Futures. Retrieved 10/10/2023 from https://www.oxfordeconomics.com/resource/global-construction- futures/#:~:text=Construction%20work%20done%20up%20from,in%20the%20 global%20green%20economy.

- Pan, Y., Zhang, Y., Zhang, D., & Song, Y. (2021). 3D printing in construction: state of the art and applications. The International Journal of Advanced Manufacturing Technology, 115(5-6), pp 1329-1348.

- Pasupathy, K., Ramakrishnan, S., & Sanjayan, J. (2023). 3D concrete printing of eco- friendly geopolymer containing brick waste [Article]. Cement and Concrete Composites, 138, Article 104943.

- Perrot, A. (2019). 3D printing of concrete: state of the art and challenges of the digital construction revolution. pp 1-16. https://doi.org/10.1002/9781119610755

- Petersmann, S., Huemer, M., Hentschel, L., & Arbeiter, F. (2023). Effects of simulated body fluid on the mechanical properties of polycarbonate polyurethane produced via material jetting. Polymer Testing, 120, Article 107977.

- QOROX. (2023). Showcase of Several 3D Concrete Printing Projects with New Zealand. . Retrieved 16/10/2023 from https://cybe.eu/webinars/webinar-qorox/

- Rajabi, S., El-Sayegh, S., & Romdhane, L. (2022). Identification and assessment of sustainability performance indicators for construction projects. Environmental and Sustainability Indicators, 15, Article 100193.

- Raza, M. H., & Zhong, R. Y. (2022). A sustainable roadmap for additive manufacturing using geopolymers in construction industry. Resources, Conservation and Recycling, 186, Article 106592.

- Salandin, A., Quintana-Gallardo, A., Gómez-Lozano, V., & Guillén-Guillamón, I. (2022). The First 3D-Printed Building in Spain: A Study on Its Acoustic, Thermal and Environmental Performance [Article]. Sustainability (Switzerland), 14(20), Article 13204. https://doi.org/10.3390/su142013204

- Samudrala, M., Mujeeb, S., Lanjewar, B. A., Chippagiri, R., Kamath, M., & Ralegaonkar, R. V. (2023). 3D-Printable Concrete for Energy-Efficient Buildings. Energies, 16(10), 4234.

- Saunders, M., Lewis, P., & Thornhill, A. (2009). Research methods for business students. Pearson education.

- Shahrubudin, N., Lee, T. C., & Ramlan, R. (2019). An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manufacturing, 35, pp 1286-1296.

- Singh, R., Gehlot, A., Akram, S. V., Gupta, L. R., Jena, M. K., Prakash, C., Singh, S., & Kumar, R. (2021). Cloud manufacturing, internet of things-assisted manufacturing and 3D printing technology: reliable tools for sustainable construction. Sustainability, 13(13), 7327.

- Skilton, M., & Hovsepian, F. (2018). The 4th industrial revolution: Responding to the Impact of Artificial Intelligence on Business. Springer, Switzerland. https://doi.org/https://doi.org/10.1007/978-3-319-62479-2

- Stats NZ. (2020). Greenhouse Gas concentrations. Stats NZ. Retrieved 15/10/2023 from https://www.stats.govt.nz/indicators/greenhouse-gas-concentrations/

- Tay, Y. W. D., Panda, B., Paul, S. C., Noor Mohamed, N. A., Tan, M. J., & Leong, K.

- (2017). 3D printing trends in building and construction industry: a review.

- Virtual and Physical Prototyping, 12(3), pp 261-276.

- Taylor, C., Roy, K., Dani, A. A., Lim, J. B. P., De Silva, K., & Jones, M. (2023). Delivering Sustainable Housing through Material Choice. Sustainability (Switzerland), 15(4), Article 3331.

- Thai, H.-T., Ngo, T., & Uy, B. (2020). A review on modular construction for high-rise buildings. Structures, 28, pp 1265-1290.

- Tirth, V., & Ghori, S. W. (2021). Cost–Benefit Analysis and Environmental Impact Assessment of 3D Printing Applications in Building Construction in Oman. Fourth Industrial Revolution and Business Dynamics: Issues and Implications, pp 89-107.

- Tuvayanond, W., & Prasittisopin, L. (2023). Design for Manufacture and Assembly of Digital Fabrication and Additive Manufacturing in Construction: A Review.

- Buildings, 13(2), Article 429.

- Volpe, S., Sangiorgio, V., Fiorito, F., & Varum, H. (2022). Overview of 3D construction printing and future perspectives: a review of technology, companies and research progression. Architectural Science Review, pp 1-22.

- Volpe, S., Sangiorgio, V., Petrella, A., Notarnicola, M., Varum, H., & Fiorito, F. (2023). 3D printed concrete blocks made with sustainable recycled material. Vitruvio, 8(Special Issue), pp 70-83.

- Wasti, S., & Adhikari, S. (2020). Use of Biomaterials for 3D Printing by Fused Deposition Modeling Technique: A Review [Review]. Frontiers in Chemistry, 8, Article 315.

- Xiao, B., Chen, C., & Yin, X. (2022). Recent advancements of robotics in construction.

- Automation in Construction, 144, Article 104591

- Zhang, N., & Sanjayan, J. (2023). Extrusion nozzle design and print parameter selections for 3D concrete printing. Cement and Concrete Composites, 137, Article 104939.

Asad Ur Rehman Bajwa Massey University. 6 PUBLICATIONS 3 CITATIONS